A properly bonded epoxy coating not only holds up under heavy foot traffic, but it also resists damage from abrasions and impacts. Designed to protect the concrete floor beneath, the added benefit of epoxy floor coatings is that they continue to look good and perform well even under heavy wear.

Epoxy is, by far, one of the longest lasting floor coatings available, but its longevity depends heavily on its environment and whether or not it was properly installed. Some epoxy floor coatings in residential areas have been known to last for decades, but most industries can expect 5 or 10 years of use before the coating needs to be recoated or just touched up.

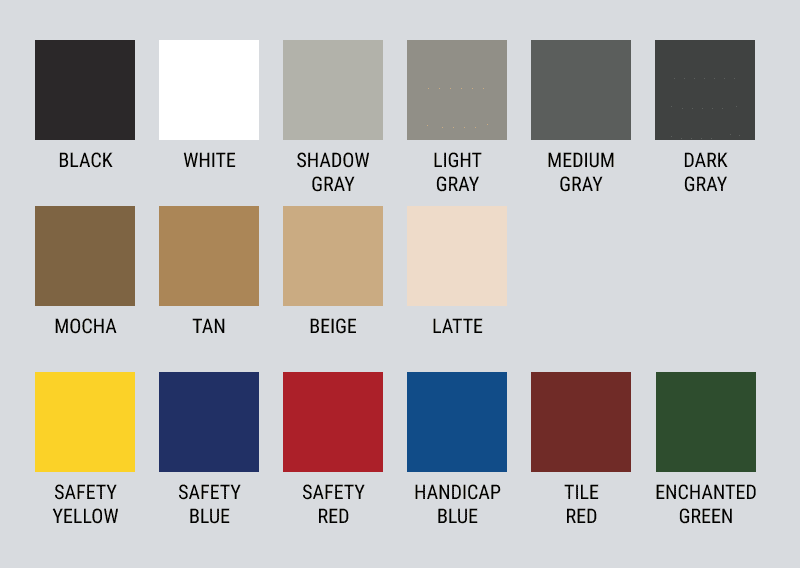

COLOR

Epoxy floor coatings come in virtually any color, and the aesthetic appeal doesn’t end there. From safety floor striping to company logos, colors can be applied in any pattern. As long as they are not overexposed to UV light, the colors stay vibrant for the lifespan of the coating.

TEXTURE

Textures like metallic make floors shimmer with satiny confetti-like flakes, and quartz creates a textured surface that’s also slip resistant.

In addition to style, the rough texture of quartz makes the floor slip-resistant, which is why quartz floors are perfect for:

- Manufacturing plants and warehouses that handle frequent spills

- Schools, particularly for athletic showers and locker rooms

- Commercial parking garages

- Retail and commercial environments

- Healthcare facilities

Epoxy floors are not only good-looking and long-lasting, but they’re also a safe and hygienic flooring option.

SANITATION

Epoxy’s impermeability to liquids makes it impossible for mold and bacteria to grow in the porous concrete below the epoxy coating. Additionally, some epoxy coatings have additives that make it unreceptive to bacterial growth that are common to veterinary clinics and hospitals.

SAFETY

Slip-Resistance. For safety, other aggregates can be added epoxy that make the floor slip-resistant, which is ideal in any setting, but especially in manufacturing facilities and warehouses.

ESD. Where electronic equipment exists – such as in an electronic manufacturing facility – so does electrostatic. Electrostatic dissipative epoxies (ESD) prevent and reduce the effect of static discharges, thereby also protecting equipment and workers.

Floor Striping. Particularly helpful in warehouses with forklifts or other moving machinery, floor striping is a popular safety feature for epoxy flooring. In a warehouse where employees are sharing the floor with drivers of heavy machinery, striping keeps everyone in their own lane and helps traffic to flow more efficiently. Floor striping can also aid in organization. Sections of the warehouse floor can be labeled to identify where various tools, supplies and equipment belong.